Your premier source for metal fabrication services in California. With over 55 years of experience, we specialize in producing high-quality metal stampings for a wide range of industries. And as a family-owned and operated business since 1967, we take pride in our craftsmanship and attention to detail.

Our extensive catalog boasts over 1000 stampings designed specifically for the lamp and lighting industry. In addition to our catalog line, we also offer custom and customer-owned metal stampings that are proudly made in America. We work closely with our clients to create metal stampings that meet their unique specifications and requirements.

Besides metal stamping, California Tool & Die also offers CNC production machining, Wire EDM services, manual welding, and assembly services.

Besides metal stamping, California Tool & Die also offers. CNC production machining, and Wire EDM services.

If you’re in need of prototype development services, look no further than California Tool & Die.

If you’re in need of prototype development services, look no further than California Tool & Die.

We understand the importance of flexibility in today’s business environment. That’s why we can work with all of your inventory requirement programs, including vendor management systems and blanket order processing.

At California Tool & Die, we have a fully staffed and equipped die shop that enables us to build and maintain all of our tooling in-house.

Our press shop is equipped with a wide range of capabilities, from 5-ton secondary operation machines to coil fed OBI presses up to 150 tons.

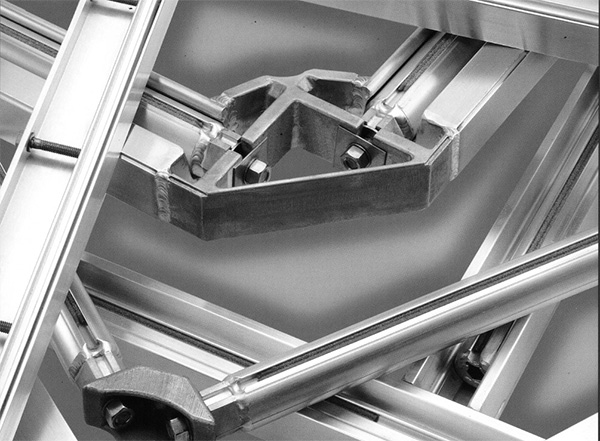

In addition to metal stampings, we operate Eino Products, a full-service aluminum fabrication company specializing in aluminum welding.

.Founded in 1967, California Tool & Die (McWilliam & Son, Inc.) is a family-owned precision manufacturing company based in Azusa, California. With more than 50 years of experience, we specialize in deep-draw metal stamping and tool & die work — producing both catalog and custom parts.

We operate two main product lines:

Metal stampings for the lighting industry (with over 1,000 cataloged parts).

Aluminum screen-printing frames, including a patented retensionable draw-bar design under our Diamond Chase brand.

We combine traditional craftsmanship with modern manufacturing: our processes include CNC machining, wire EDM, welding, drilling, spot welding, assembly, and more.

Our in-house die shop enables us to build and maintain tooling (not just for ourselves, but for other companies, too). We also provide rapid-turnaround die maintenance for clients who don’t have their own die facilities.

It is recommended to inspect your roof at least twice a year, in the spring and fall. Signs include.

It is recommended to inspect your roof at least twice a year, in the spring and fall. Signs include

It is recommended to inspect your roof at least twice a year, in the spring and fall. Signs include

Whether you need a new die for your production line or want us to build one for your use in our shop, California Tool & Die can help. We have the expertise to design and build simple blanking dies, compound blank and draw dies, complex deep draw dies, progressive dies, multi-cavity dies, secondary punching and/or notching dies, secondary draw dies, and engraving dies. No matter the complexity of the die you require, we have the skills and equipment to get the job done right.

We provide top-quality des roofing services tailored content

© 2025 Topfix. By All Rights Reserved.